Radiation Shielding Materials

Natural background radiation is constantly present in the environment, but elevated exposure can occur during certain medical imaging tests and industrial tasks. Whether you visit a hospital for an X-ray, work in a nuclear power plant, or conduct industrial inspections with radiographic equipment, radiation shielding is crucial to protect you from the unseen dangers of ionizing radiation. Learn everything there is to know about radiation shielding materials to help you make the right selection for your application.

What is Radiation Shielding?

Radiation shielding is the practice of using materials to block or reduce radiation exposure. Shielding works by absorbing or deflecting radiation, preventing it from reaching areas where exposure could harm people or sensitive equipment.

Radiation comes in various forms—including alpha particles, beta particles, gamma rays, X-rays, and neutrons—each with unique characteristics. While alpha and beta particles are easy to block with simple barriers like paper, clothing, or thin plastic, the penetrating power of gamma rays, X-rays, and neutrons demands more robust shielding materials.

Exposure to excessive levels of radiation can lead to acute health problems, long-term risks like cancer, and damage to electronic equipment. Shielding ensures that people and systems stay safe from the harmful effects of this invisible energy.

Applications for Radiation Shielding

Radiation shielding is used across a variety of fields, including:

- Medical imaging and treatment like X-rays, CT scans, and radiation therapy

- Nuclear power plants, where shielding contains radiation within reactors and waste storage areas

- Industrial applications, from oil and gas to aerospace, that rely on radiographic testing

- Research laboratories that work with radioactive isotopes

Common Radiation Shielding Materials

Different types of radiation require specific shielding materials.

Gamma and X-Ray Shielding Materials

Gamma and X-rays are high-energy forms of electromagnetic radiation, making them challenging to shield. Here are the go-to materials for these types of radiation:

- Lead is a highly effective material for radiation shielding thanks to its high density and atomic number. Lead is affordable, highly available, and unmatched in its shielding performance. However, lead is heavy, which can make installation and transportation cumbersome. Moreover, the material is toxic, requiring careful handling and disposal.

- Lead composites blend lead with materials like rubber, vinyl, or plastic. This approach creates shielding products that are lighter and more flexible than pure lead, making them ideal for applications like personal protective equipment (PPE). Lead composites maintain excellent radiation-blocking properties while offering improved user comfort.

- Lead-free shielding materials include tungsten, tin, bismuth, and antimony. These materials are safer for humans and the environment. They’re more expensive than lead, but the improved sustainability and reduced health risks make them attractive alternatives.

- Concrete is a versatile shielding material for large-scale applications like room shielding. Adding high-density aggregates, such as barite or magnetite, enhances the shielding effectiveness of concrete. It’s cost-effective and durable but may require significant thickness to achieve the desired level of protection.

- Steel is another strong, versatile option, often used in combination with other materials like concrete. It provides structural support while contributing to radiation attenuation.

Neutron Radiation Shielding Materials

Neutron radiation, commonly encountered in nuclear reactors and research settings, requires specialized shielding due to its unique properties. Here are some commonly used materials:

- Water is an excellent neutron moderator, slowing fast neutrons and capturing them effectively. It’s often used as a coolant and shielding material in nuclear reactors. Water is inexpensive and easy to use, but its application is limited to specific environments.

- Concrete can be used for neutron shielding when it incorporates hydrogen-rich aggregates, such as boron or polyethylene, which enhance the material’s ability to capture neutrons.

- High-density polyethylene (HDPE) is a lightweight, hydrogen-rich material that effectively absorbs neutrons. It’s frequently used in portable shielding products and areas where weight is a concern. HDPE is non-toxic and easy to work with, making it a popular choice for custom shielding solutions.

Radiation Shielding Products and Design

The design and materials used in shielding are tailored to the specific type of radiation and the operational environment. Here are some common products and designs used in radiation shielding.

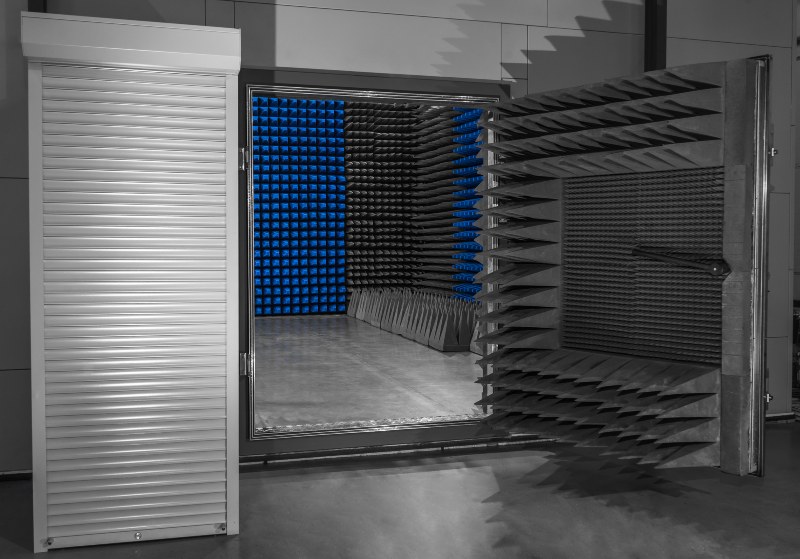

Room Shielding

In environments like hospitals, nuclear facilities, and research labs, radiation isn’t confined to a single machine or area. That’s where room shielding comes into play. Entire rooms are built with materials like lead-lined walls or high-density concrete to contain radiation.

For example, hospital X-ray rooms are equipped with lead-lined drywall and doors to ensure radiation doesn’t leak into adjacent spaces. Similarly, nuclear reactors use massive amounts of concrete and specialized metals to shield against gamma and neutron radiation.

Leaded Glass and Curtains

Visibility is often important in high-radiation environments. Leaded glass provides a transparent yet protective barrier in X-ray room windows and control booth partitions, allowing technicians to monitor procedures without exposure.

Lead curtains offer retractable or fully mobile shielding options. These leaded rubber or vinyl sheets protect against low-level or secondary radiation. Freestanding versions can be moved around the building, while those on ceiling-mounted tracks can serve as temporary partitions.

Worn Personal Protective Equipment

PPE such as lead aprons, gloves, and thyroid collars protect the most vulnerable parts of the body. This reduces the cumulative radiation exposure for professionals and patients in medical imaging, research labs, and other high-radiation settings. Modern designs often incorporate lead-free materials to improve comfort without compromising protection.

Lead-Lined Containers

Containers lined in lead allow for the safe storage and transportation of radioactive materials. These containers are durably constructed for safety in high-radiation environments, such as medical facilities, nuclear power plants, research labs, and industrial applications. They’re often used for holding radioactive isotopes, waste, and other materials.

Contact Us for Expert Advice and Quality Materials

Nuclear Lead Co. Inc. has over 50 years of experience crafting high-quality radiation shielding solutions. From lead shielding for medical imaging rooms to custom storage solutions for radioactive materials, we take pride in offering products that protect people, facilities, and equipment from the harmful effects of radiation. Let us partner with you to create safe, efficient environments. Contact us today for expert advice or to learn more about our innovative products.